– Full Service Machine Shop –

Cylinder Head Porting and Valve Jobs

Custom Headers & Full Exhaust Systems

Open Lathe & Mill Time

Custom Design and Fabrication

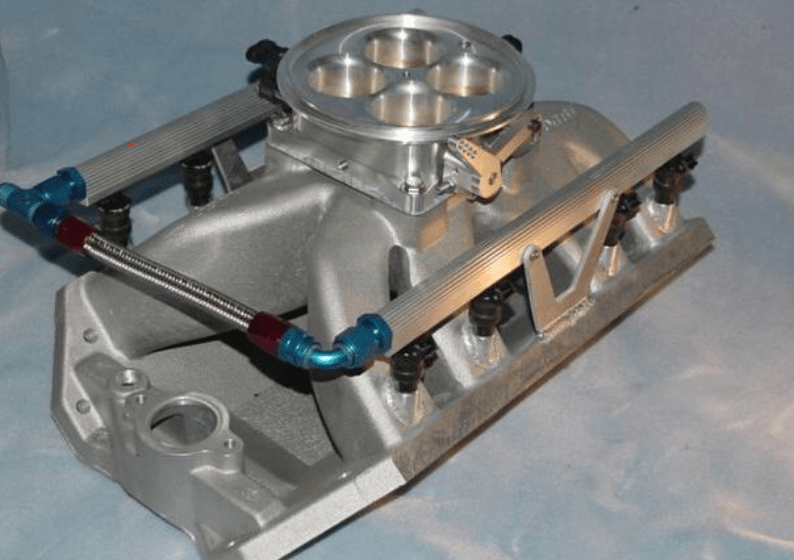

EFI Manifold Conversions

We start with a clean single plane intake supplied by the customer. The manifold is fixtured in a milling machine and the center to center measurement of each port is determined using the digital indicator. A 3/4″ hole is drilled into each runner. Injector bosses are pressed into place and set at the correct depth to keep the nozzle tip recessed from the port. The bosses are the TIG welded into place. The manifold is turned upside down, the excess boss material is cut away, and a porting tool is used to finish the job.

Once the intake is back on its feet, we use our hi-flow rail stock to create custom fuel rails.

Stanchions are then welded or bolted to the manifold to support the fuel rails.

Any ports necessary for sensors or vacuum accessories are drilled and tapped.

Injector & main engine harnesses are modified or custom built to the manifold and customer requirements.